Romain Michon 250B

Contents

First Ideas for the Final Project (01/27/2013)

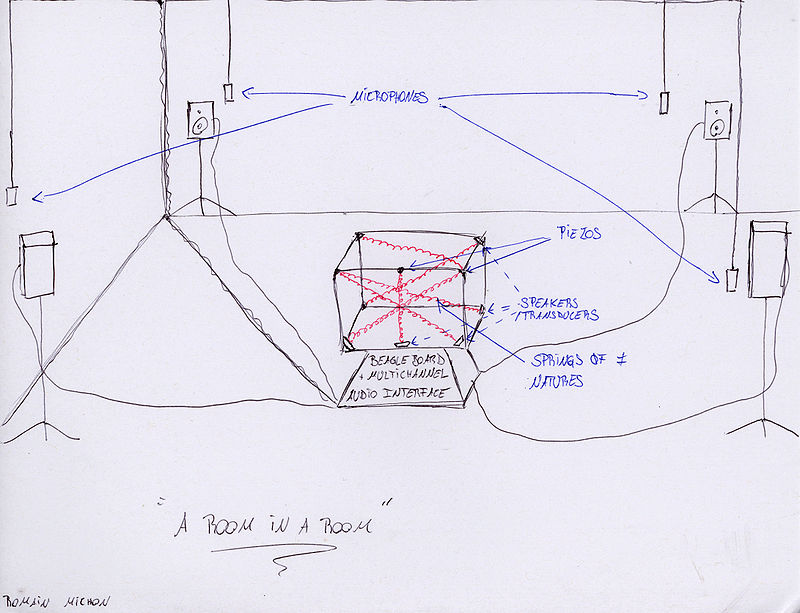

Global View

The idea is to create a space where several static microphones (4 ?) would pick-up the sound happening in the room and would send their signal to a structure that would act as a sound processor. The processed sound would be then played back with speakers.

The structure I'm thinking about is an open cube made of a metal frame where many springs would be stretched at different positions. One extremity of every springs would be fasten to a transducer and the other extremity to a piezo. The idea would be that the sound produced by the transducer would be carried to the piezo by the spring that would modify the spectral content of the sound.

The signal from the microphones could be first received by a multi-channels audio interface connected to a small computer (BeagleBoard?) that would route the signal to one spring or another. It would also be interesting to process the sound on the computer and to associate a specific sound effect to each spring. A kinect could be used to detect the position of a person in the installation space and could control to which spring the sound would be sent. Finally, we could use a 4 channels playback system that would allow to spatialize the sound around the cube.

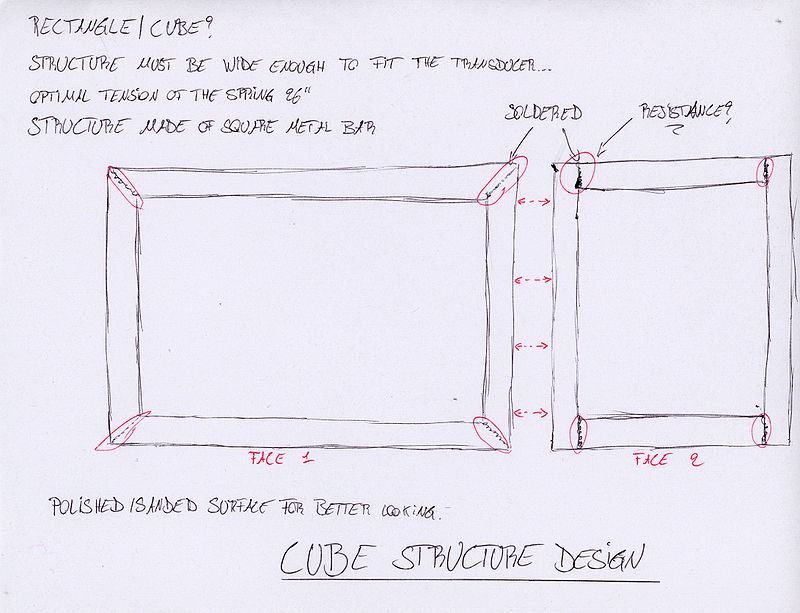

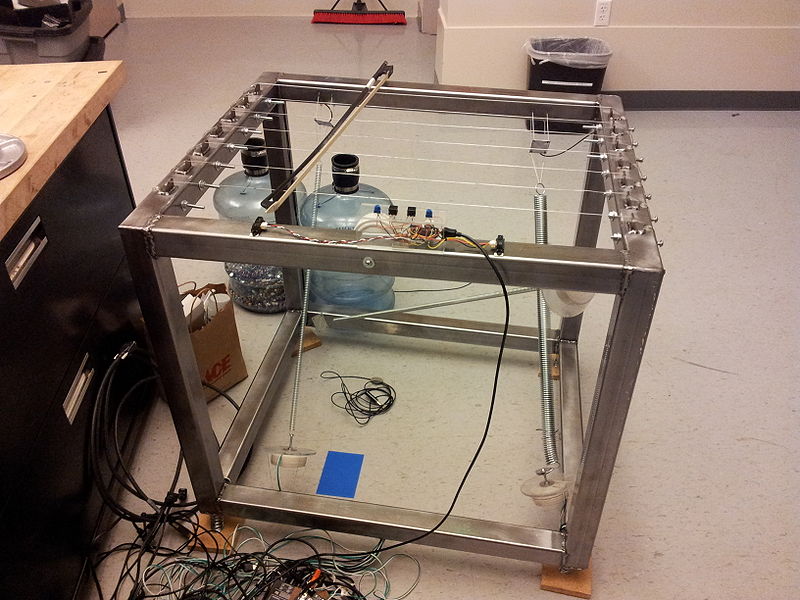

The Cube Frame

The cube's frame would be based on a structure made of square metal bars. Its dimension has yet to be defined but it will depend on the maximum stretching length of the springs. As it is shown on the sketch above, one single metal bar can be used to build the cube structure. It will be cutted and then soldered. Another important thing to define is the width of the metal bars.

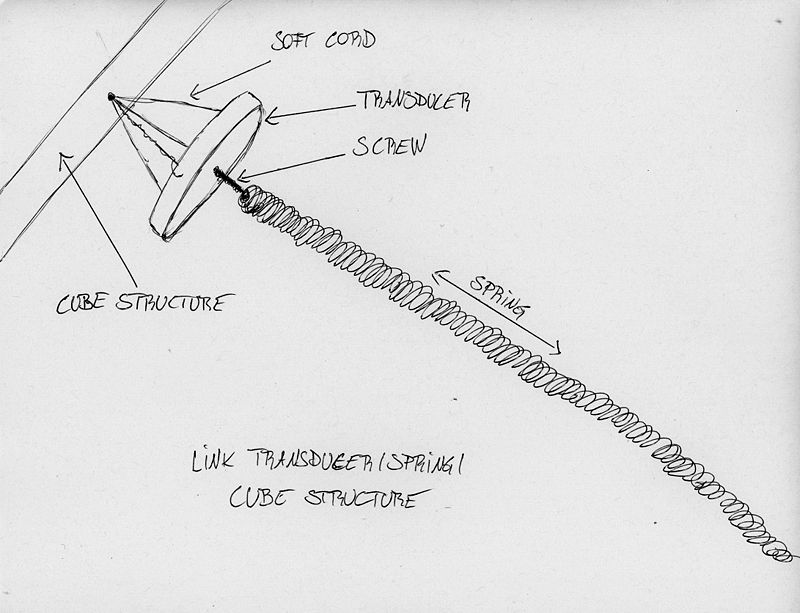

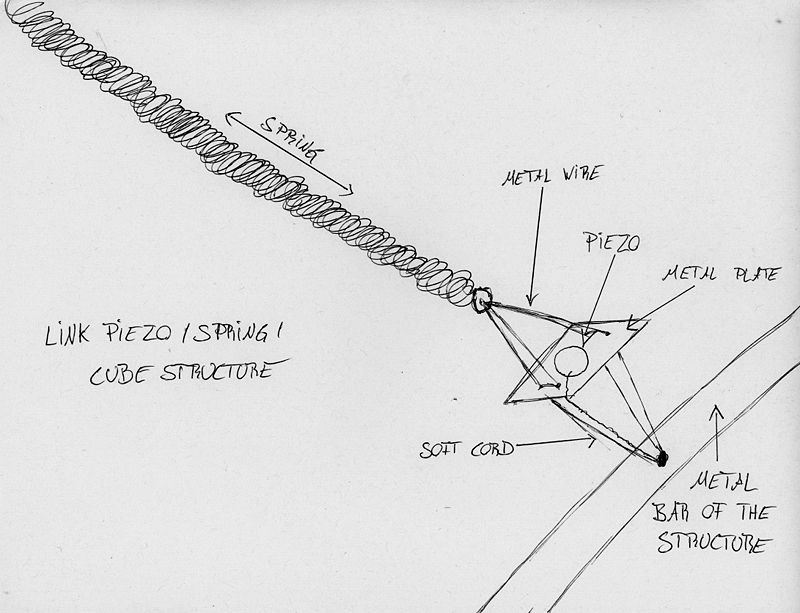

Transducer/Spring/Piezo System

One of the most important factor to take into account for the design of the system that will hold the spring streched is that the spring should apply as less pressure as possible on the piezo. Also, as it wont be possible to totaly hide the transducers in the cube structure (too big), we have to think about a nice way to integrate them in the installation.

Design

Based on the constraints mentionned above, the best think I came with looks like that:

The soft cords isolate the springs from the rest of the structure which is important if we wanna keep them independant. Although, it might also be interesting to use metal wires instead in order to create more interactions between the different elements of the structure... The piezo is glued on a small piece of metal that holds the spring.

Test

In order to see how well a spring behave when it is used to process sound, I did the following test:

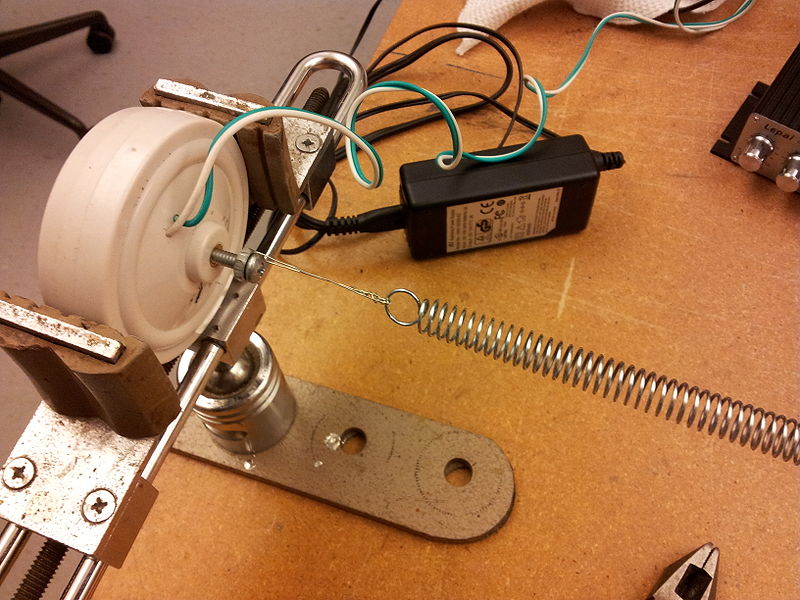

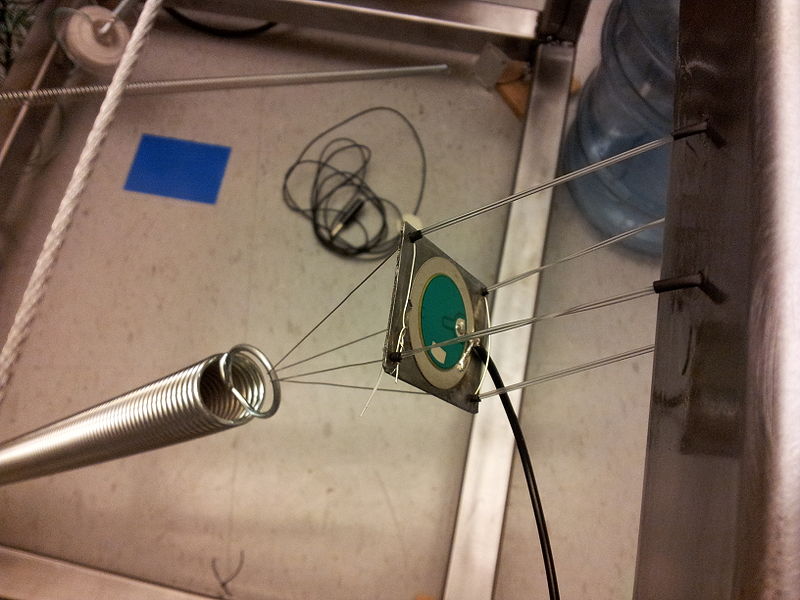

Global view of the experiment.

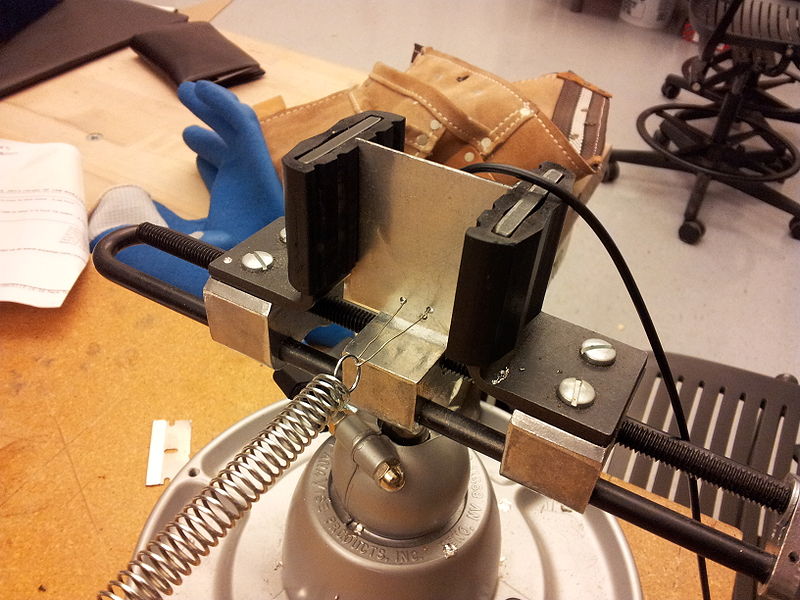

Tranducer to spring.

Spring to piezo. The piezo is glued on the other side of the metal plate.

To test the system, the sound of a youtube video of The Little Prince was played in the spring. The result was recorded and is available here.

Additional Features and Thoughts

I think the most interesting part of this installation is that it creates some kind of "mise-en-abîme": the sounds of the room are processed in the cube which acts as a smaller room with its own acoustical properties.

Touching and moving the springs when a sound is played in it provides a great control on the nature of the generated sound: the audience should be able to easily access the springs to touch them.

Adding some vibrators to shake the cube could create intersting effects.

The graphical aspect of the installation is very important: LEDs could be added.

Cube Structure Building (02/07/2013)

Just got the 2 inches wide still metal bars! The first step was to cut them in half using a circular saw. The hard job was to cut the 45° angles at each extremity of every bar. I first used the circular saw for that but I had to grind them afterward to get perfect angles.

I used an arc welder to assemble the different pieces of the cube...

Once the cube was built, I drilled holes on its top in order to put screws in them that I could use to stretch the strings.

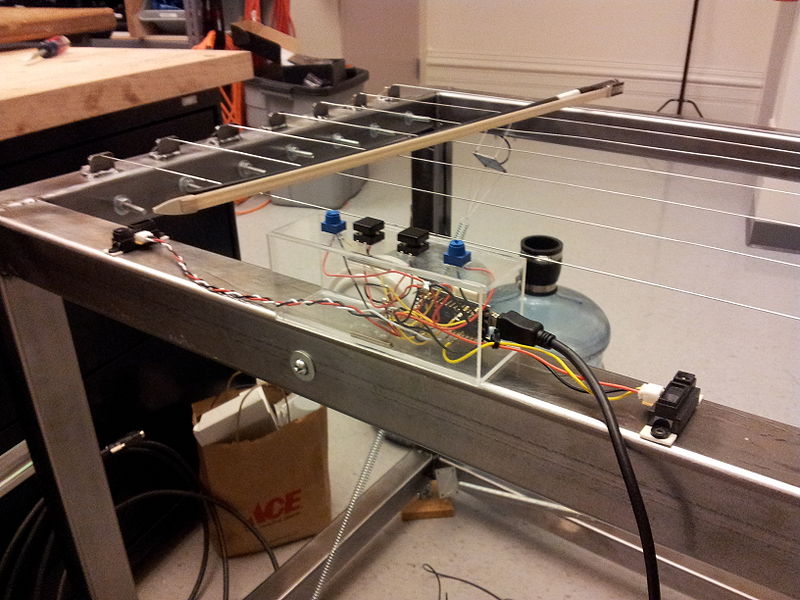

Putting everything together (03/07/2013)

I welded little metal bridges on the cube to stabilize the strings and to avoid non-linearities. I spend a lot of time sanding the frame to make it very clean and I then painted it with a transparent gloss to prevent it from corosion. I finally mounted the springs as well as the strings on it.

As I'm using the cube for another class where a live performance is involved, I built a little control interface that is made of an arduino, 2 buttons, 2 knobs and 2 distance sensors. It can be fasten to the cube with magnets which also makes it very easy to remove.

The electric signal generated by the piezo is sent to a multichannel audio interface that is connected to a BeagleBoard.

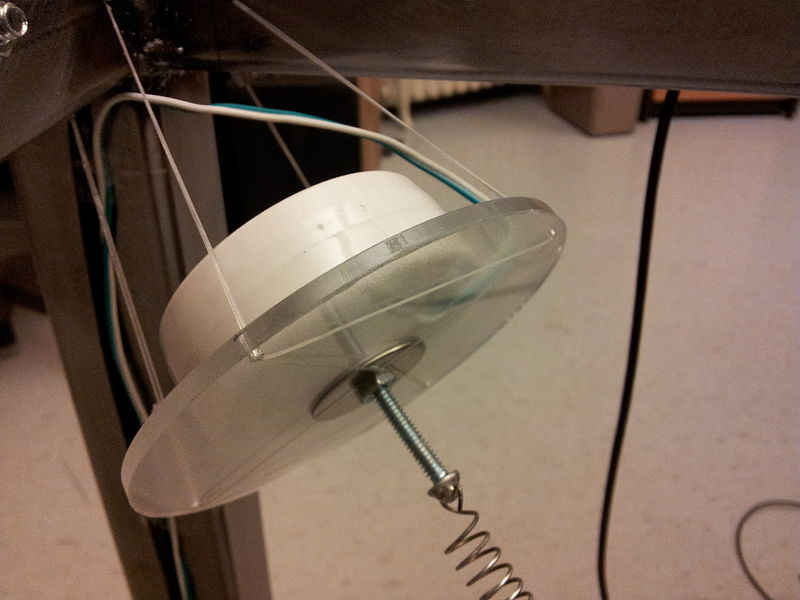

I laser cutted acrylic pieces to fasten the transducers to the cube using a soft wire in order to avoid coupling with the cube structure.

Finally, I mounted the cube on springs to isolate it from the ground and to make it "float".