Product design

Conceptual design

... creativity, collaboration, interdisciplinary and innovation are some of the keys to a successful product

Detailed design / cad-cam-Cae

Reverse engineering

PARAMETRIC CURVES AND SURFACES

Most of his academic activities are related to the methodologies used at eah stage of the product design process, from the conception of the product until its realization.

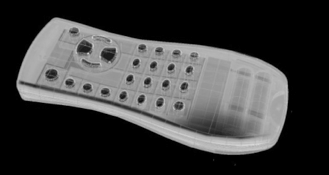

The conceptual design stage is the most important of the design process as it involves the definition of the requirements which have to be translated into a user interface design. A concise statement of the product, what it is, what it is not, user roles, requirements, objectives, constraints and other elements are needed to obtain an adequate product.

Creativity, collaboration, interdisciplinary and innovation are some of the keys to a successful product.

Once the conceptual definition of the product is completed, it needs to be detailed. Nowadays, Computer Aided Design tools are essential in the product definition.

Since 1999, Javier has been teaching the use of 3D parametric solid and surface modeling techniques at Tecnun. Between others, ProEngineer or RhinoCeros have been the CAD systems used for this purpose.

Top-down design methodologies and complex surfaces modeling techniques are the base of detailed design. The students have had the possibility of participating in the conceptual and detailed design of many products in collaboration with some companies.

In order to work appropriately with complex surfaces models, it is necessary to have a solid knowledge of the mathematics behind the parametric curves and surfaces.

Bezier, B-spline or NURBS (Non-Uniform Rational B-Splines) are different mathematic expressions of parametric curves and surfaces.

A parametric curve or surface can be expressed as function of one or two parameters respectively. A parametric curve is based on a control polygon and a parametric surface is based on a control net. Other parameters on a curve definition are the order, the basic function, the knot vector values or the weight factor.

Tangency or curvature continuity are important issues to be taken into account when combining more that one curve or surface. Curve and surface fitting techniques, as interpolation and approximation are also important to manipulate complex shapes.

Reverse engineering techniques are commonly used for product inspection and product design. In the last years, 3D portable scanners have become very popular and more affordable, Handyscan is an example of it. It is quite easy to scan an object using a 3D scanner and obtain a cloud of points. The main difficulty lies on obtaining the parametric surfaces that fit to this collection of points.

Although there are some applications that automatically generate surfaces from cloud of points, it is still necessary to complete the process manually. Advanced surface modeling skills are needed in order to complete this step.

Face scanning devices are used to scan faces for different purposes, as medical, face recognicion or biometrics. 3dMD is an example of face scanning system.