Lab 6 HAPTICS

The goal of this lab is to introduce some simple one-dimensional active

force-feedback using a motor and encoder. We start either with a

small

knob or with a stick that has a force sensor on the top; other devices

could be attached to the motor shaft. Each haptic effect can be

coupled to

a

sound by sending OSC to Pd. Different haptic effects suggest

different

sounds; different sounds suggest different effects. What are the

most interesting mappings? Which are appropriate, controllable,

even "expressive". Try each sound control with and without the

motor turned on. Are there some that simply cannot be played

without haptics?

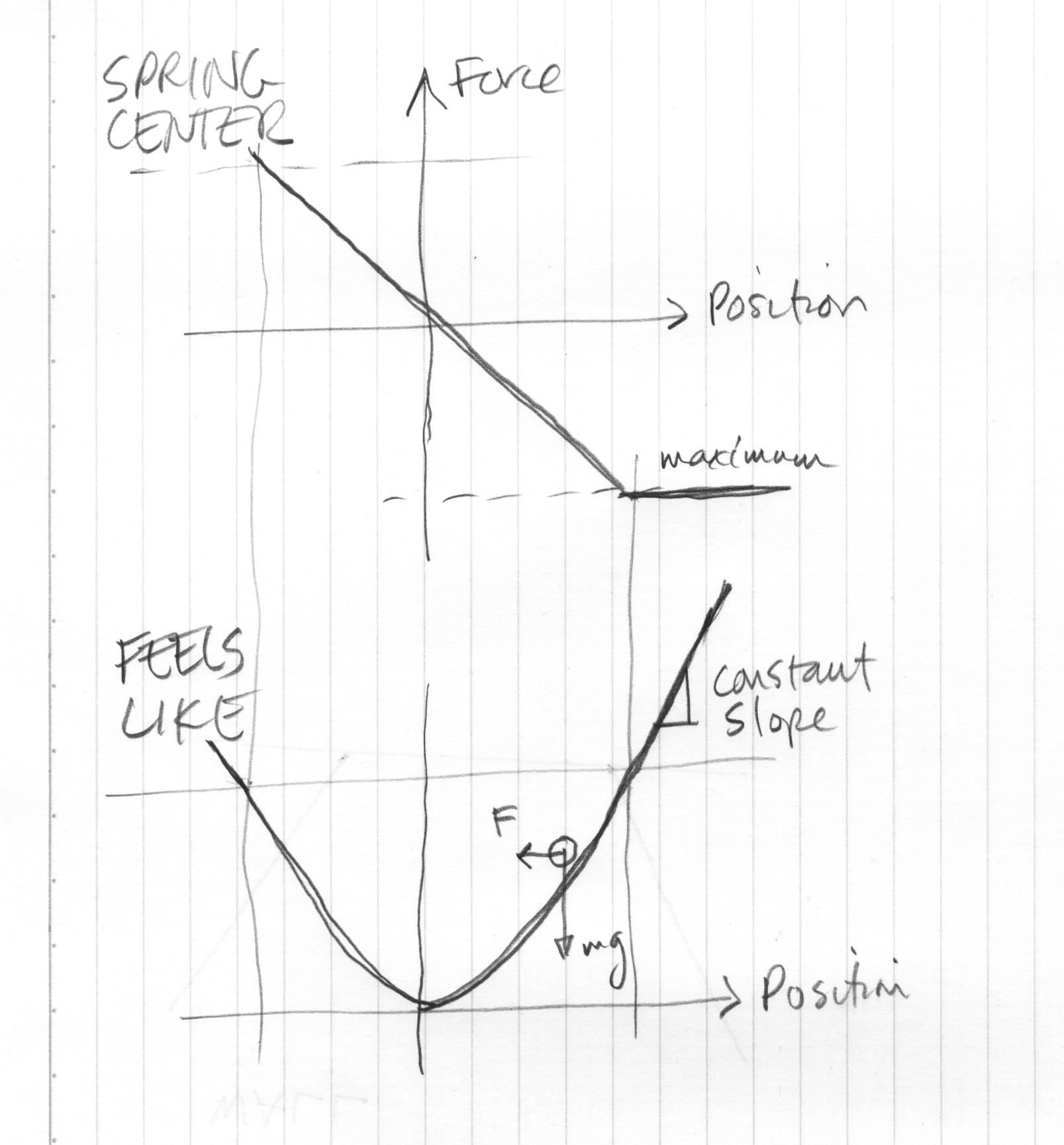

PROFILES - First we compute forces as a function of just position: for

every encoder position, there is a specific force. Think of it as

a profile or landscape -- a resisting force feels like pushing

something up a slope, as the force increases,

the slope increases. Think of the

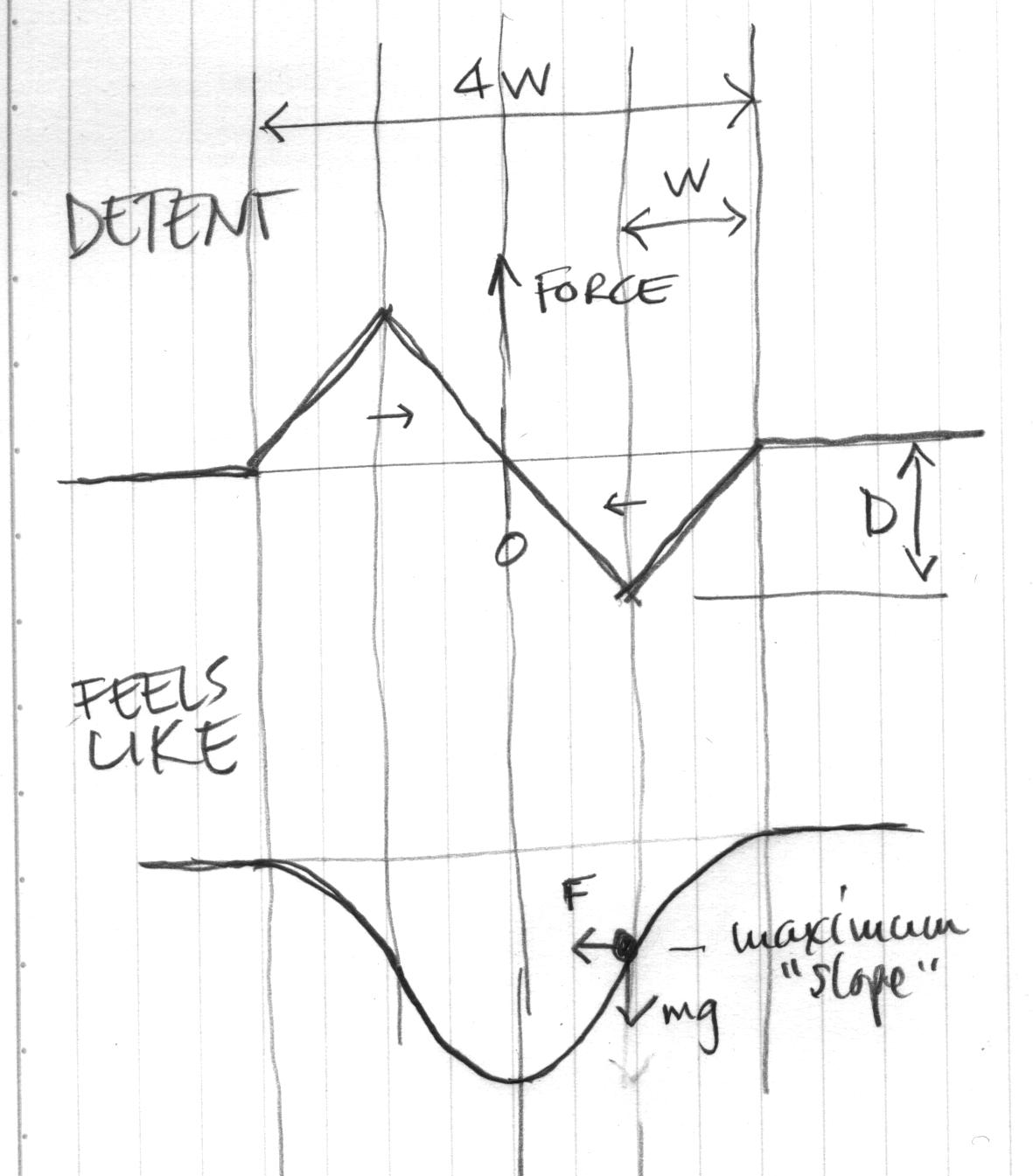

spring-centering of motortest.c as a "valley", wall.c has no force

until you reach the wall, bumps.c and detents.c are all variations of

force as "slope". Textures can be rendered as series of

bumps. Stability: A

very stiff wall is hard to make "stable": first, the

encoder and force values are discrete making for "stair steps" or

"zippers" and the calculations in fixed-point reducing resolution, more

importantly the update rate must be high. You can explore various

resolutions and rates.

TIME - Forces that vary in time can be pre-programmed (tick.c). A

short positive then negative force, if it is quick enough feels like a

click. When pressing against a spring, a click simulates a

contact being made.

DYNAMICS - We can increase the apparent "mass" - giving the knob a

twist, gets it going. You can simulate simple mass-spring

oscilators (think of it as a pendulum). Without measuring force

(we only measure position) we cannot reduce the "mass" or

"damping". The human hand acts as a "damper" stabilizing an

oterwise oscillating system; the hand can also be a spring-mass coupled

with the virtual spring-mass just like a drum stick bouncing on a snare.

FRICTION - can be simulated with a combination of texture, dynamics and

even pre-programmed

0. Set up

a. connect the ribbon cable from PORTX on the

motor board to PORTD on the AVR. Check the orientation: make sure that

both headers have pins 9-10 at the same side of the ribbon cable (e.g.

BLACK)

b. wire the motor's encoder (grey cable) to

AVR/Protoboard: White to D2, Green to D3, Red to +5v and Black to GND.

D2 and D3 are the two external interrupts and represent Phase A and

Phase B from the encoder.

c. connect the power for the motor directly to the

15v supply pins, Yellow on the left pin and Black on the center pin of

the two that have been attached to U5. This is the same place that we

picked up 15v for the OpAmps in Lab 4.

d. plug in the Spyglass LCD to PORTC.

e. for the stick, connect the FSR Red to +5v, Black

to GND, White to A0 for a2d conversion.

g. load Lab6 on to your 250a directory

download: these program files files and unpack them in your lab 6 directory using tar -xvf

h. add these files to your ~/avrlib/ccrma directory.

cp -r /usr/ccrma/web/html/courses/250a/labs/lab6/avrlib_ccrma_lab6.tar ~/avrlib/ccrma

cd ~/avrlib/ccrma

tar -xvf avrlib_ccrma_lab6.tar

1. motorspy (spring-centering)

a. run "motorspy.c"

~>cd ~/250a/lab6/programs/motorspy

~>make

load

b. The LCD should display

Encoder: Force: and Duty:

i) Try moving the knob/stick left

and

right.

ii) What is the maximum duty?

iii) If you press on the FSR the

forces will increase.

b. Try 'motortest.c' It is the same program but with

out the

Spyglass

display.

c. Try 'motorosc.c' It is the same program but with

out

the Spyglass

display and with OSC. After loading motorosc.c, start motorosc.pd.

2. wall

a. run "wall.c"

~>cd ~/250a/lab6/programs/wall

~>make

load

b. Look at the code for wall.c.

i) Make the wall "stiffer"; what

if it's too stiff?

ii) Make the walls further appart or

closer together.

3. bell (one wall, sending to Pd)

a. run "bell.c"

~>cd ~/250a/lab6/programs/bell

~/250a/lab6/programs/bell>make

load

b. run "wallbang.pd"

~/250a/lab6/programs/bell>pd bell.pd

c. when you "hit" the wall, a sound should be

triggered.

i) Change the sound file in the

Pd patch by loading "snare" or "kick".

ii) By varying the wall stiffness (SW7

or SW7) can

you get an intentional bounce?

iii)

What stiffness (k) best matches the sound chosen?

iv) With the right stiffness, you should

be able to get a "drum roll".

4. bumps and detents, plucks and friction.

A "bump" is a slope up to a round

top

and a

slope down on the other side.

A "pluck" is a slope up like a wall but followed by

an abrupt drop in force at the top.

Stick-slip "friction" is many small plucks in a row.

a. run "detent", "detents" and "pluck".

b. can you make a "bump" instead of a "detent"?

c. think of sending some OSC messages at the right

time/positions.

d. vary W, D, S to match the sounds from Pd.

5. tick - timed forces

a. run "tick.c"

~>cd

~/250a/lab6/programs/tick

~/250a/lab6/programs/tick>make

load

b. Look at the code for tick.c

i) Make the ticks longer, larger,

more frequent.

6. walltick - "tick" on wall "entry"

a. run "walltick.c"

~>cd

~/250a/lab6/programs/walltick

~/250a/lab6/walltick>make

load

b. run "snare.pd"

~/250a/lab6/wallbang>pd Snare.pd

c. what is the "right" place (distance

into the

wall), magnitude, etc.

d. try matching the wall stiffness and the tick to

different sounds.

7. pendulum

8. spring, mass and damping

references:

<~/avrlib/ccrma/osc.h>

<~/avrlib/ccrma/osc.c>

not included in <~/avrlib/docs/>

see schematics and manual for MotorBoard on Pascal's site: AVR boards

motor data sheet: <~/Lab6/RelianceMotor.jpg>