Experimental Wind Instruments

Adnan Marquez-Borbon - CCRMA

Rob Ernst - Cogswell Polytechnical College

This project began as a curious exploration of some unusual musical

possibilities for acoustic tubes.

It consists of two parts: one being the excitation of multiple tubes by

a single source and second,

the seamless introduction of electronic feedback into an acoustic tube.

Multiphonic Bass Clarinet (MBC)

Goal:

Our Goal was to make a multiphonic clarinet that could be used in a

live setting as a droning

instrument. In order to achieve multiple different pitches from a

single wind instrument,

we had to use multiple tubes of varying lengths that all protruded from

a single mouthpiece.

The goal was to make a drone that had some very interesting beating

created by the different

frequencies of each tube, so we cut the tubes according to the desired

frequencies.

The other thing we had to think about was that it is going to be played

in a live setting,

possibly simultaneously with a keyboard. So the instrument had to be

relatively light weight

and compact. Lastly, for amplification as well as greater sonic

versatility, we decided to add

small condenser microphones to the ends of each pipe, so that we could

plug it into a computer

interface and further manipulate, or just amplify and record the sound.

A cylindrical bore was chosen due to the facility it provides in

constructing an instrument.

After researching some of the dimensions of Bass Clarinets it was found

that the inner diameter

of the bore is approximately 0.92 inches and that the length of the

bore from mouthpiece to bell

lies around 42-43 inches (some sources state variations ranging from 37

to 51.9 in).

The lowest frequency of the instrument is a sounding D2 (73.42 Hz).

Using the formula for tubes closed on one side, fn = (2n-1)(v/4L), it

was proceeded to calculate

the length of the tubes based on the lowest frequency desired.

Materials:

- 1" PVC Pipe (10')

- 90 degree angle connectors (2)

- 90 degree T splitters (3)

- Bass clarinet mouthpiece, ligature and bass clarinet reeds (2 1/2)

- Small condenser mic capsules (4)

- Capacitors (4)

- Resistors (4)

- 9V batteries and connectors (4)

- 1/4 in phone plugs (4)

- Various wire

The inner diameter of the PVC pipe is close to our ideal bore diameter

and in practice,

the difference in diameter does not affect much of the acoustic

characteristics of the tube.

The Build:

The first thing we had to do was to figure out how long to cut the

piping to get our selected

frequencies. The frequencies we were shooting for were: 73.42 Hz (D2),

110.0 Hz (A2),

146.8 Hz (D3), and the last tube we wanted to be able to slide from

130.8 to 167.8 Hz (C3-E3).

In order to determine the length needed for each frequency we used the

formula: Fn = (2n-1) v/4L

With this formula we determined that the proper lengths for those

frequencies were:

1.17 m, 0.779 m, 0.584 m, and 0.656 m. But we could not just cut our

pipes to this length,

because we also needed to take into account the distance from the

mouthpiece to the beginning

of the sounding pipes. This distance would act as part of the pipe and

change the frequency.

So when we subtracted that distance our final numbers were 0.93 m,

0.619 m, 0.424 m, and 0.416 m.

Then we measured our long pipe and started cutting. While we were at it

we also cut some 1 1/2 in

pieces of pipe to mate our angled connectors near the mouthpiece.

After cleaning up the edges all we had to do was simply put it

together. We attached the mouthpiece

and gave it a try. The first noticeable problem was that it was very

hard to make all four pipes

to sound at once. It takes a very focused breath and if you stray a

little from it the instrument

can squeak or only sound some of the pipes. After a little bit of

practice it started

to sound pretty good.

pipes

connectors

detail

tube pitches

assembly

finished MBC

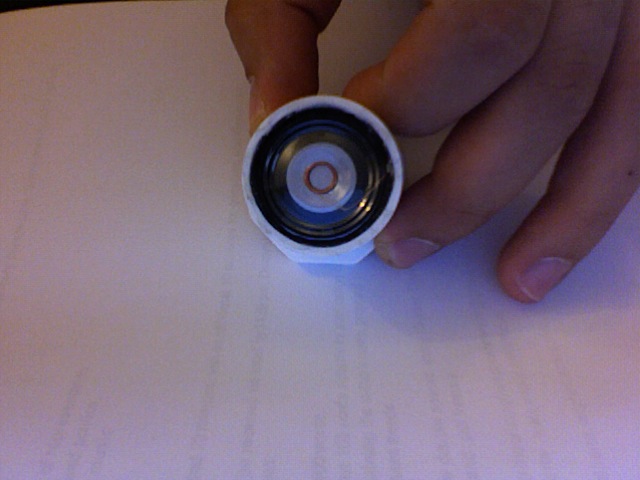

microphone

microphone

closeup

The last thing to do is to build four

microphones for each tube and mount them with zip ties.

I built a simple program in Pd

and

ChucK ,

as well as a graphic interface in

Processing

to use with

the instrument in a live performance setting. You can find them here:

MBC patches

Here's what the instrument sounds like:

MBC

with freeverb

MBC

with feedback delay network

Feedback Bass Clarinet (FB2C)

Goal:

To incorporate an electronic feedback system into an acoustic instrument.

Materials:

- 1" PVC Pipe (6')

- 90 degree T splitters (3)

- 1" PVC cap (1)

- Bass clarinet mouthpiece, ligature and bass clarinet reeds (2 1/2)

- Small condenser mic capsule (1)

- Capacitors (1)

- Resistors (1)

- 9V batteries and connectors (1)

- 1/4 in phone plugs (2)

- mini speaker (1)

- Various wire

The Build:

Make one

microphone of the previously mentioned type, and make the

mini speaker connection

by directly connected to a 1/4" mono plug (speaker (-) to ground and

(+) to signal).

This instrument is very straight-forward in its construction, however

the speaker must be

fixed into the T coupling in such a way that air leakage is avoided.

Otherwise, the instrument will

"speak" at the length were there leak lies in (which should be a higher

pitch than desired).

The mini-speaker is mounted on the inside of the cap. The inside

diameter had to be increased with

a dremel tool because the speaker was a bit too big. Then we drill and

hole at the back of the cap

so the speaker cables can go out. Once we have everything set, we hot

glue the inside of the cap

opening and mount the speaker. Finally, with the cables poking out of

the back of the cap, we hot glued

the hole and cables so we can have a seal and avoid any air leakage.

Finally, the driver is mounted on the side opposite to the tube so that

the sound coming from it is

has a direct path to the microphone. The mouthpiece will be put on the

mid coupling. The arrangement

is a bit odd, but otherwise getting feedback to occur will be a bit

more difficult.

driver and cap

driver and cap

driver

driver

cap top view

cap top view

finished FB2C

finished FB2C

A simple program in Pd and ChucK was written to be used with the

instrument.

Here they

are: FB2C

NOTE: After realizing that having the feedback loop go through the audio

interface produced some bad sounding digital clipping and that the

gain control was a bit difficult to control, an analog

mixer along with a SP-303 sampler we used instead.

An auxiliary output of the mixer is sent to the input of the sampler,

and the output of the sampler is sent to the aux return bus of the mixer.

Finally, one of the main outputs (or control room out) is sent to the driver

in the tube. Appropriate gain staging is done in order to achieve feedback.

Just make sure that the signal is not "on the red" if you plan on recording,

otherwise the signal will clip and it will not sound good at all.

Once we have feedback, we can put any effect we desire in the sampler.

In this case delay and pitch shifting tend to work quite well.

Other routing schemes were tested, but in the end the result was the

same.

Hear the instrument: WARNING! IT CAN GET VERY LOUD

FB2C

(6' pipe @ ~47 Hz)

FB2C

(16' pipe @ ~17.6 Hz)

adnanm[at]ccrma.stanford.edu

Last modified: 1 December 2008